Trapped in stagnation: what are the chances of Mykolaiv Alumina Plant after nationalisation?

- News of Mykolaiv

-

•

-

- Kateryna Sereda

-

•

-

19:24, 18 June, 2024

Three months ago, it became known that Ukraine had completed the nationalisation of the Mykolaiv Alumina Plant, which was confiscated from Russian oligarch Oleg Deripaska a year ago. To date, this is the largest nationalisation object that the State Property Fund of Ukraine (SPFU) has taken over.

On 20 March 2024, on its website, the SPFU expressed an unequivocal position on its plans to sell the confiscated Russian property, the proceeds of which «would be used to support and restore Ukraine». Since then, we have not heard or seen any action by the State Property Fund in relation to this enterprise.

While working on this material, «, NikVesti» contacted a number of government agencies, including the State Property Fund, with questions about the current situation at MGZ, which is considered one of the largest alumina plants in Europe. In addition to production capacity, understanding the situation at the plant and its future is also important in terms of environmental safety - there are two sludge pits there that require constant maintenance, which costs hundreds of millions of hryvnias annually.

Who manages the company and how?

We addressed the management body, the State Property Fund of Ukraine, directly with questions about the company's operating hours, the number of employees, product balances, wage arrears and how the sludge fields are maintained. However, they advised us to contact the company and its interim manager.

Currently, until a new CEO is elected, these powers are being exercised by Oleksiy Medvid, a leading engineer for the operation of decomposition equipment «and calcination and decomposition areas». In a commentary to «NikVesti», Alexey Medved said that he has been in charge of the plant since 1 June 2022.

«"I have been working at the plant for 20 years. Before that, I was the head of the trade union. I came here in 2004 as an electrician»," said Alexey Medved.

He was the one who organised protests by the plant's employees outside the courts as part of the case «Stop Sludge» 4 years ago, which concerned compensation to residents of Mykolaiv Oblast who suffered from red sludge emissions.

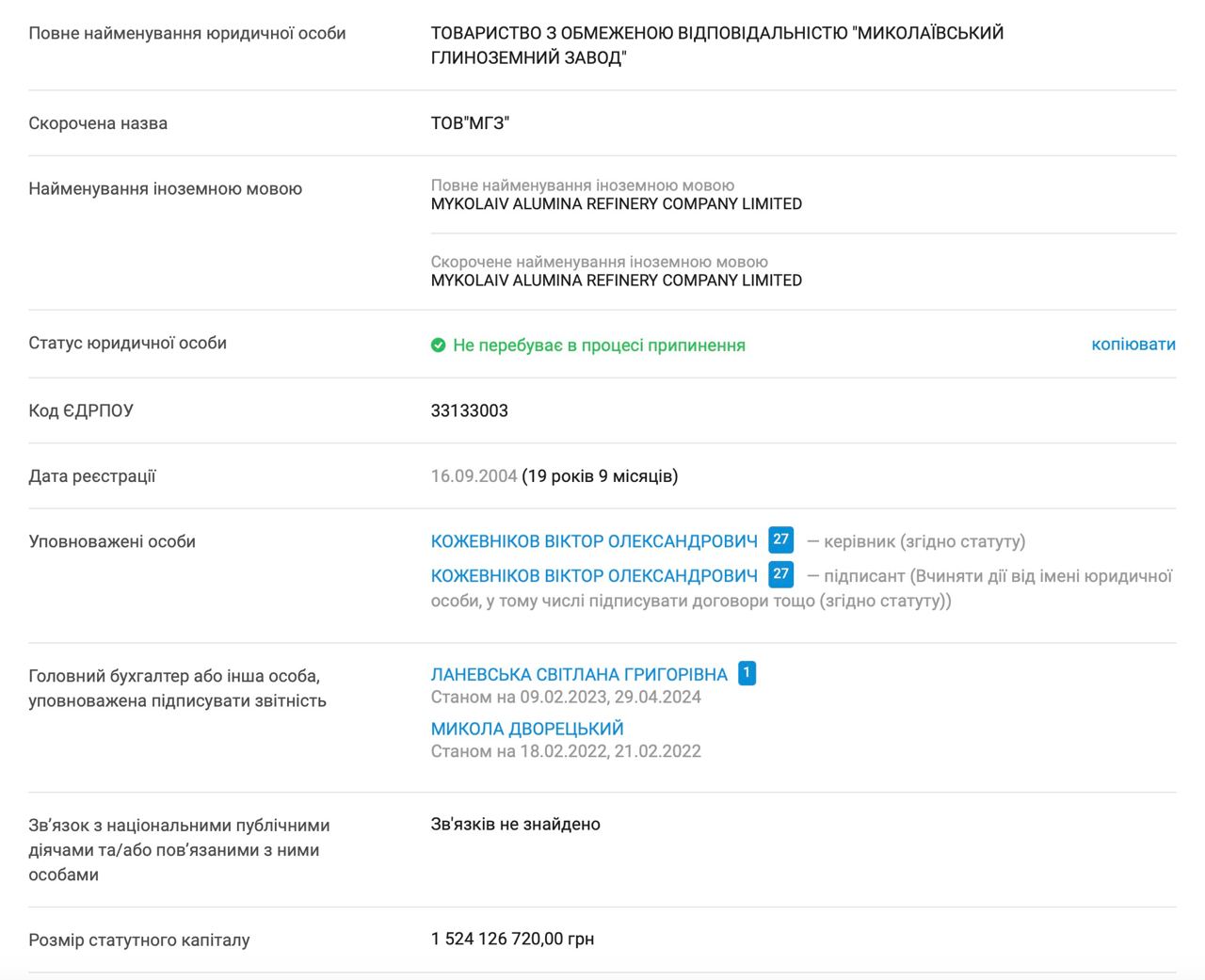

However, as of 18 June 2024, the register still lists Viktor Kozhevnikov, a Russian protege, as the director, as evidenced by the YouControl system. According to «NikVesti», he left Mykolaiv in the spring of 2022.

Out of five thousand workers, 400 remain

The company currently employs 400 people. Before the full-scale war, there were about 5,000 workers.

«These 400 specialists take care of the company, its equipment and two sludge fields. This is the only area that is actually functioning at the enterprise. The sludge is still there, it is not being supplied there, but it is stored. We need to keep an eye on the dams»," said Alexey Medved.

"The company does not receive any assistance from the state, and all financial needs (for example, paying employees' salaries) are met from its own savings.

«We have suspended labour relations with 80% of our employees. Not fired, but suspended. Those who expressed a desire are still working. We have retained specialists in the areas and departments who know the technology and equipment. So that they can train people and launch the plant in the future»," said Alexey Medved.

"Today, the main task of the plant is to maintain the sludge fields.

«The most important thing is the irrigation system. It has been disrupted. These are pipes with «fountains». This is a constant moistening of the surface. To avoid dust. We also have auger conveyors, which turn the sludge over when they walk, preventing very dry sludge from being on the surface. We treated the sludge fields with special reagents. This is a film to prevent dusting. We don't do that now.

When the plant was in operation, the water that accumulated in the first sludge field went into the processes. Now the process is stuck - the water is just arriving at the field. And now it is causing a problem with erosion. We are engaged in pumping. We are making major technological changes, using some of the technological equipment from»," said Alexey Medved.

Is Mykolaiv Alumina Plant an environmental «» time bomb?

The plant, which has been out of operation for three years now, has become many times more dangerous for the environment than when it was operating at full capacity. This position was expressed by the head of the State Ecological Inspectorate, Igor Zubovich, in response to an information request from «NikVesti» regarding the situation at MGZ since the start of the full-scale war.

Between August 2022 and September 2023, 12 cases of uncontrolled dusting from sludge pits No. 1 and No. 2 of the Mykolaiv Alumina Plant were recorded at MGZ.

It should be noted that the so-called sludge fields at NGZ are 49 million tonnes of waste stored on an area of about 400 hectares on the territory of NGZ.

The red sludge at MGZ is stored in two sludge pits. The first was commissioned in 1980 with a design capacity of 20 million cubic metres of sludge. Sludge SF No. 1 is located on the first lifting terrace of the Dnipro-Bug estuary, in dams 22 metres high on the estuary side and 12 metres high on the slopes. The sludge is stored using the wet method - it was stripped of water for ease of transportation.

Sludge SF No. 2 was commissioned in 2007. The sludge is stored using the dry method of thickening. The design capacity is 1.5 million cubic metres per year.

Red sludge is a solid or paste-like mixture of waste resulting from the separation of aluminium oxide (a raw material for aluminium production) from bauxite, containing iron, titanium, silicon oxides and water, characterised by a strong alkaline environment.

According to a certificate obtained by «NikVesti» from the State Environmental Inspectorate, on 19 July 2022, Mykolaiv Alumina Plant reported that shelling in the area of sludge pit No. 2 had made it difficult to treat the surface of the stacked red sludge in the sludge pit bowls, which had led to risks of red sludge dusting.

As a result, the company treats only one third of the area of sludge pit No. 2: «military operations in the area of sludge pit No. 2 and damage to the dust suppression system lines, making it difficult to repair them; inability to maintain the dust suppression system due to the blocking of the company's accounts. At the same time, sludge pit No. 1 is being maintained in full by wetting the territory using the company's own resources».

Twice in August 2022, once in September 2022 and once in January 2023, MHP reported that due to increased wind speeds, uncontrolled dusting from one of the sludge pits was observed, which could cause contamination of land outside the sanitary protection zone. At that time, the company put in place a dust suppression system at sludge pit No. 2.

At the same time, due to a lack of personnel, the company was unable to carry out dust suppression works on the beaches of sludge SF No. 1.

Uncontrolled dusting of sludge from the company's slag fields continued in 2023: in May, July, August (twice) and September (4 times).

Until July 2022, the dust suppression systems at sludge pit No. 2, including the restoration of the system after shelling, were maintained by a contractor that stopped providing services because MMPP had not paid them for almost six months.

The reason for this was the inability to pay for further services due to the suspension of all expenditure transactions on all accounts of Mykolaiv Alumina Plant since the start of the full-scale war in February 2022, as decided by the National Bank of Ukraine.

«The suspension of all expenditure transactions (except for salary and tax payments) and the seizure of accounts as part of criminal proceedings led to the suspension of production activities at «MGZ» and disruption of the normal operation of red sludge ponds. Currently, there is no possibility of purchasing materials and items that could be used to prevent the destruction of the dam of sludge pit No. 1 and to engage contractors to carry out the relevant work for the purpose of»," the State Environmental Inspectorate said.

It is also noted that in the spring of 2023, the operation of the company's sludge pits became emergency:

- The filling of the working bowl of sludge pit No. 1 with sludge water exceeded the permissible level, which threatens to pollute the waters of the Bug Estuary, which is 300 metres from the sludge field.

- The critical level of accumulation of sub-sludge is in sludge pit No. 2, which has a higher alkalinity than sludge pit No. 1. Overfilling of this storage facility will lead to contamination of the adjacent agricultural land.

- There is still a problem of significant dusting of sludge in field No. 2, which can cause air pollution. This is due to the fact that there is a «dry» method of accumulation that requires constant monitoring and surface moisture.

- The sprinkler system for dust suppression (necessary to moisten the sludge), which was in place at the plant, was damaged and out of order during the hostilities.

«The situation with the undermining of the Kakhovka hydroelectric power station dam has complicated the existence of this industrial facility, which, having stopped working, has become many times more dangerous for the environment than when it was operating at full capacity... While the enterprise is not in operation, it is difficult to implement constructive measures to reconstruct and improve the safety of processing, accumulation and storage of industrial waste due to the high cost of the work. As a result, Mykolaiv Oblast will face a potential threat to public health and safety in the event of an emergency at the sludge pits of LLC «MGZ» for many years to come," the environmentalists said in a response to a request from «NikVesti».

In addition to the environmental threats associated with the maintenance of sludge ponds, in May 2022, an explosion damaged the company's fuel oil facilities as a result of artillery shelling, causing soil contamination over an area of 1200m2. In addition, in June 2022, soil was contaminated over an area of 2,500 m2.

The total amount of damage caused by soil contamination was UAH 58 million 905 thousand 747.

As part of the preparation of this material, in April 2024, we wrote a second request to the State Environmental Inspectorate regarding the state of affairs at the enterprise earlier this year. However, in response to our request, the State Ecological Inspectorate of the South-Western District (Mykolaiv and Odesa regions) reported that the company was not operating and the inspectorate did not conduct any scheduled or unscheduled inspections, and therefore no violations of the sludge SF maintenance regulations were recorded there from November 2023 to April 2024.

What are the prospects for the alumina refinery?

Last year, Rustem Umerov, then head of the State Property Fund and now Minister of Defence of Ukraine, said that it would take 60-90 days to prepare the plant for privatisation. Our interlocutors say that there are potential investors who are ready to buy the company or, for example, take it into a concession. But not in the context of hostilities and blocked waters. The Kinburn Spit, occupied by Russian troops, is 20 kilometres from the territory of the plant.

Logistics is the main issue in solving the company's problem. The sea route is the only possible way to transport bauxite (the raw material for alumina production). This is confirmed by Vitaliy Kim, Head of the Mykolaiv Regional Military Administration.

«Over the past two years, we have conducted a lot of research and talked to potential investors. We travelled to countries where there are raw materials and countries where there is consumption. There is such a scenario, but it rests on logistics, including our non-operational ports. At the moment, it does not seem possible to launch production in any form»," Vitaly Kim said in a commentary to «NikVesti».

Another option for the post-war development of the enterprise is the construction of an aluminium smelter in Ukraine. This would ensure a full cycle of aluminium production, which is needed for construction and reconstruction work in Ukraine, among other things. Cheap electricity is important for the competitiveness of such production, but given the electricity shortage in Ukraine, this is not possible.

It is also possible that the production will be completely shut down and the port infrastructure will be developed at the MGZ. In this case, the issue of maintenance of sludge pits may become a problem, which will become a burden for the budget.

The nationalisation of Mykolaiv Alumina Plant opens up new prospects and challenges for the regional economy and the environment. The immediate objectives are to ensure sustainable management of sludge fields and restore production capacities that can contribute to Ukraine's economic development in the post-war recovery. Ensuring these processes will require both government regulation and private investment, which opens up a field for dialogue between different stakeholders.

Kateryna Sereda, «NikVesti»

This publication was made possible with the support of the Partnership Fund for a Resilient Ukraine, funded by the governments of the United Kingdom, Canada, the Netherlands, the United States of America, Finland, Switzerland, and Sweden. The content of this publication is the sole responsibility of the online media "NikVesti" and does not necessarily reflect the views of the Fund and/or its financial partners.

Чому ви читаєте «МикВісті»? Яка наша діяльність найбільш важлива для вас? Та чи хотіли б ви стати частиною спільноти читачів? Пройдіть опитування, це анонімно і займе 5 хвилин вашого часу